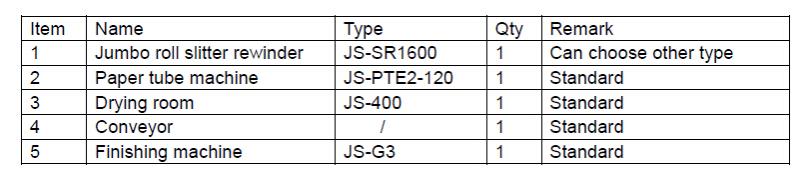

Functional Description:

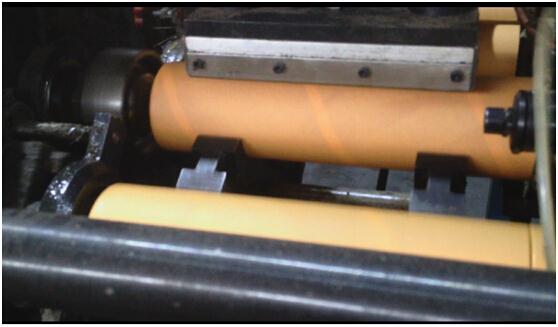

Equipped the E Series paper tube machine, design simplicity, compact and stable, with multi-functional bottom paper devices, face parchment device can be over water or not over water, single or double color can be used. Low height of the integral glue stand is easily to operate.Adopt 3kw screw pump and cycle gluing,polyurethane rubber coating, evenly scraping ; Standard equipped integral paper reel stand, adopt electric hoist to hangon the paper rollers, easy to operate .Adjusting the angle of paper reel stand automatically.

pipeline

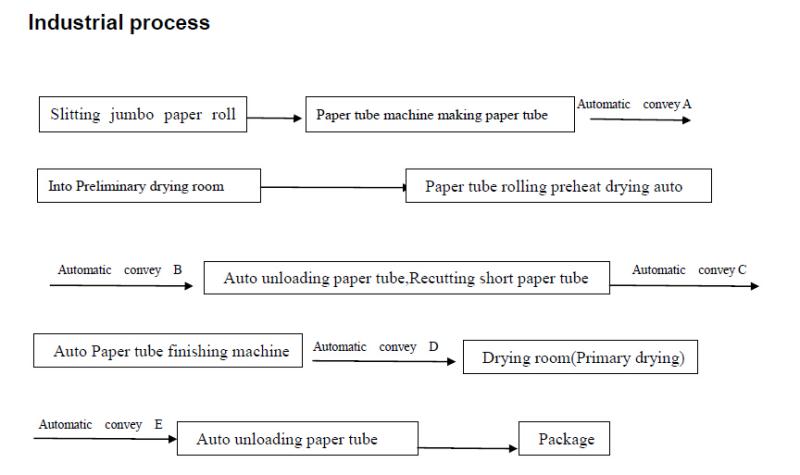

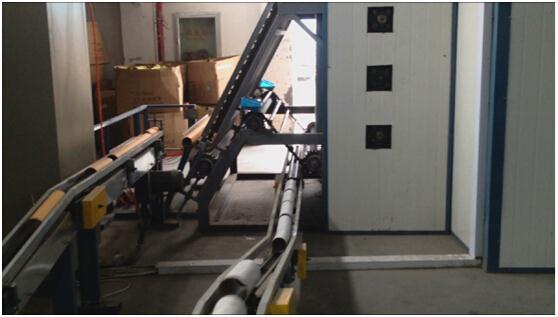

drying room by a paper tube machine making paper tube through the conveyor

belt after pre-drying zone automatically, after the pre-bake enhances the

bonding of paper, remove part of the

water so that there is a certain strength, easy paper tube be curling when it

will not cracking deformation, automatic transmission, into the drying compartment,

out of drying room,dehumidification, drying, temperature detection, fault

detection, alarm and other fully automated, without someone to look after.

Paper tube rolling slowly, gradually drying, the pros and cons of high-strength

hot air flow from the paper tube inside and outside the chamber, the proper

uniform temperature control loop, avoiding the old drying room due to the fixed

piles of paper tube placement, wind, temperature caused by uneven distribution

the size of the deformation, moisture unevenness and other defects.

3.finishing line by the re-cutting machine and grinding and curling machine production line, automatic transmission, into the re-cutting machine, unloading re-cutting machine, into finishing machine, fault detection, alarm and other fully automated, without personnel custody.

Making paper tube

Transmit to pre-drying part

Loading in recutting machine

Re-cutter part

Finishing machine

Drying room

Equipment